Substrate preparation ARDEX S 1-K Plus

The substrate must be dry, durable, load-bearing, free from dust, dirt and separation layers.

Any absorbent gypsum substrates such as gypsum plaster, gypsum board, gypsum - anhydrite screeds must always first be primed using ARDEX P 52 diluted 1:3 with water.

The gypsum plaster must be dry, compact and load-bearing, an applied layer of at least 10 mm thick, not felted or smoothed. The surface must be protected against the ingress of moisture from the substrate, e.g.: through the external wall. For this reason, the conditions must be checked before applying the sealant.

Chipboard substrates must be specially prepared in accordance with the publication "Guidance for the application and installation of ceramic tiles and panels on chipboard".

Particle boards must be V100G grade, of the correct thickness and properly rigidly and securely fixed to the substrate. They must be resistant to moisture.

Preparation and application of the material:

Application of the ARDEX S 1-K compound can be carried out with a trowel, brush or short bristle roller.

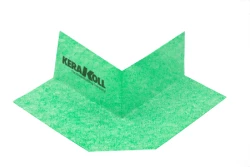

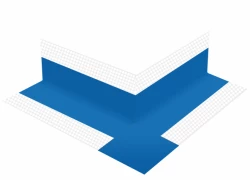

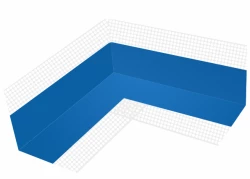

Firstly the joints of areas at risk of cracks, corners, edge joints, movement joints, penetrations and transitions are sealed using tapes, fittings and cuvettes in the ARDEX TRICOM system. Always apply a generous layer of sealant in these areas and lay down by pasting and pressing the appropriate system fitting.

The entire surface is covered with the first layer of compound of uniform thickness everywhere. In case of very rough and absorbent substrates the compound should be rubbed in and applied with a trowel.

The drying out of the ARDEX S 1-K compound depends on the thickness of the layer, the absorbency of the substrate and the conditions on site.

The second layer can be applied at normal temperatures at the earliest 2 hours after the first layer has been applied, or, for floor surfaces, when the first layer of sealant can be walked on without causing damage.

Higher temperatures and low atmospheric humidity shorten and lower temperatures and high atmospheric humidity lengthen the drying time.

The ARDEX S 1-K sealant should always be applied to saturation in two layers, such that the consumption with two layers is at least 1.1 kg/m² and the resulting after-drying sealant has a total thickness of both layers of at least 0.5 mm.

The system connection pieces: tapes, fittings and cuffs should be thoroughly coated with the second layer of sealant.

ARDEX S 1-K should be used at temperatures between +5°C and +30°C this applies mainly to the substrate but also to the surroundings, avoid working on sunny surfaces.

Laying tiles and boards ARDEX S 1-K Plus

The laying of the surface cladding on the ARDEX S 1-K sealant can be carried out approx. 6 hours after the second layer of sealant has been applied.

Use materials from the ARDEX range for bonding and laying the cladding.

The individual solution ranges for bonding and laying the cladding should be analysed with the technical data sheets of the individual products.

On working, floating and shrinking substrates it is necessary to use highly flexible adhesives from the ARDEX programme.